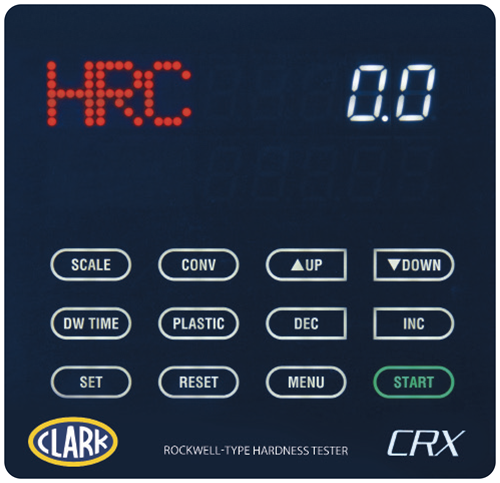

CRX Rockwell-Type Hardness Tester

Precision accuracy, repeatability and performance for all applications.

CRX Rockwell-Type Hardness Tester

The CRX Series Rockwell Type Hardness Tester is extremely reliable, built for high volume testing with precise accuracy. Available in standard, superficial and twin models, the CRX can accommodate many testing requirements. Simple to use, you can depend on the CRX Series for its performance and efficiency.

Special Features

- Capable of 30 different Rockwell-type scales (Regular and Superficial)

- Ball bearing guided spindle mechanism\

- Automatic and manual load starting

- Easy “zero” setting with audio alert

- Hardness conversion display for many scales

- Upper and lower limits capability with OK/NG display

- Easy to read LED panel display

- Plastic measurement mode comes standard

- One piece, heavy-duty cast housing

- Conforms to tolerances per ASTM & ISO 17025 Standards

ITEM | CRX-1e/CRX-1 | CRX-2e/CRX-2 | CRX-3e/CRX-3 |

| MINOR LOAD | 10 kgf (98.07 N) | 3 kgf (29.42 N) | 3 kgf (29.42 N) / 10 kgf (98.07 N) |

| TEST LOAD | 60 – 100 – 150 kgf 588.4 – 980.7 – 1471 N | 15 – 30 – 45 kgf 147.1 – 294.2 – 441.3 N | 15 – 30 – 45 kgf 147.1 – 294.2 – 441.3 N 60 – 100 – 150 kgf 588.4 – 980.7 – 1471 N |

| MINOR LOAD POSITION SETTING | Automatic setting (electronic sound monitoring.) | ||

| LOAD CONTROL | Automatic (loading, holding, removing method) | ||

| DWELL TIME | 1-999 sec (key entry in units of seconds) | ||

| PLASTIC MEASUREMENT | Standard function (one-touch selection), time up to hardness value display after release: 1 to 999 sec | ||

| HARDNESS CONVERSION | Hardness conversion capable in compliance with ASTM (E-140) | ||

| HI / LO CRITERIA | Upper and lower limit settings and HI / OK / LO display (HR 0 to 130, min. 0.1 hardness increment) | ||

| SCALE DISPLAY

| C,D,A,G B,F,K,E H,P,M,L V,S,R | 15N, 30N, 45N, 15T, 30T, 45T, 15W, 30W, 45W, 15X, 30X, 45X 15Y, 30Y, 45Y | C, D, A, G, B, F, K, E, H, P, M, L, V, S, R, 15N, 30N, 45N 15T, 30T, 45T 15W, 30W, 45W, 15X, 30X, 45X 15Y, 30Y, 45Y |

| OUTPUT SIGNAL | RS232C (Baud rate: 9600 bps) | ||

| RS-232 OUTPUT & PRINTOUT MODES | 1 - Measurement data only

PRINTOUT MODES 2 - Measurement data and evaluation results (max.value, min. value & OK/NG) 3 - Measurement data and conversion data 4 - Measurement data, conversion data and evaluation results (max. value, min. value & OK/NG) 5 - Measurement data and average value 6 - Maximum depth of indenter and measurement data | ||

| ACCURACY | Conforms to tolerances per ASTM E18 / E140 / D785 / ISO 6505-2 / ISO 6508-2 | ||

| MAX. SPECIMEN HEIGHT | 10” (255mm) / 17” (435mm) | 10” (255mm) / 17” (435mm) | 8.5” (225mm) / 15” (405mm) |

| MAX. SPECIMEN DEPTH | 6.5" (165mm) | 6.5" (165mm) | 6.5" (165mm) |

| DIMENSIONS | W 7.7" (196mm) x D 19.2" (487mm) x H 32.3" / 38" (820mm / 965mm) | ||

| WEIGHT | Aprx. 190 Lbs (87 kg) | Aprx. 190 Lbs (87 kg) | Aprx. 200 Lbs (99 kg) |

| POWER SUPPLY | 120 VAC 1Ø 2A / (AC 100~240V) Please Specify | ||

STANDARD ACCESSORIES | |||

| Hardness Standard (HRC) | 1 | -- | 1 |

| Hardness Standard (HRB) | 1 | -- | 1 |

| Hardness Standard (HR30N) | -- | 1 | 1 |

| Hardness Standard (HR30T) | -- | 1 | 1 |

| Diamond Indenter | 1 “C” | 1 “N” | 1 “C” & “N” |

| 1/16” Carbide Ball Indenter | 1 | 1 | 1 |

| 1/16” Carbide Balls Indenter | 4 | 4 | 4 |

| Anvil - 2 1/2" (60mm) Flat | 1 | 1 | 1 |

| Anvil - 1 1/2" V-Shape (40mm) | 1 | 1 | 1 |

| Machine Cover, Accessory Box, Manual, Leveling Leg Set, Conversion Chart | |||