Polishing Compounds / Abrasives

Showing all 9 results

-

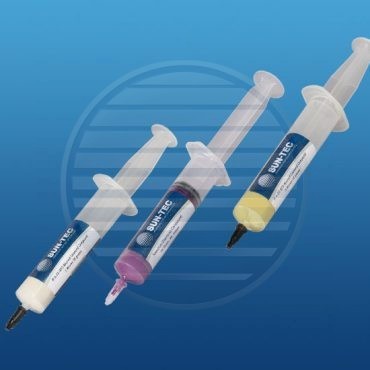

Diamond Polishing Suspension Monocrystalline

Select options This product has multiple variants. The options may be chosen on the product pageDiamond Compounds and Slurries – Two types of diamonds are offered: monocrystalline and polycrystalline. The most commonly used is monocrystalline. The polycrystalline, is typically used on hard-to-polish materials such as ceramics, tool steels, and super alloys. It has more facets or cutting edges and keeps its cutting ability by being less friable than the monocrystalline. The diamond suspensions are water-based while the compounds contain no water.

-

Diamond Polishing Suspension Polycrystalline

Select options This product has multiple variants. The options may be chosen on the product pageDiamond Compounds and Slurries – Two types of diamonds are offered: monocrystalline and polycrystalline. The most commonly used is monocrystalline. The polycrystalline, is typically used on hard-to-polish materials such as ceramics, tool steels, and super alloys. It has more facets or cutting edges and keeps its cutting ability by being less friable than the monocrystalline. The diamond suspensions are water-based while the compounds contain no water.

-

Diamond Compound Paste Monocrystalline

Select options This product has multiple variants. The options may be chosen on the product page -

Diamond Lapping Oil Extender

Select options This product has multiple variants. The options may be chosen on the product pageFor use with All Diamond Compounds and Suspensions. Used as a lubricant with Diamond Suspensions and Pastes. Contains no water.

-

Ultra Diamond Extender Fluid

Select options This product has multiple variants. The options may be chosen on the product pageFor use with All Diamond Compounds and Suspensions Used as a lubricant with Diamond Suspensions and Pastes. Alcohol Based and Water Free.

-

Colloidal Silica Slurry

Select options This product has multiple variants. The options may be chosen on the product pageColloidal Silica – A silica solution that is used for final polishing usually on an Imperial Cloth. Nominal particle size is 0.05 microns. Colloidal silica is convenient to use, works on many different alloys, and the abrasive does not settle over time. Colloidal silica is not conductive to etch-attack polishing.

-

Aluminum Oxide Abrasive Powder

Select options This product has multiple variants. The options may be chosen on the product pageAluminum Oxide or Alumina – Aluminum oxide or alumina exists in two allotropic forms (1) alpha, which has a hexagonal crystal structure, and (2) gamma, which has a cubic crystal structure. Alpha alumina removes metal faster and is more suitable for rough polishing, while gamma alumina has slower metal removal rates but produces a better finish. Gamma B (0.05 micron) is used for final polishing steps, typically on a Suncloth Polishing Cloth. Aluminum oxide is excellent for most etch-attack polishing methods.

-

Aluminum Oxide Polishing Powder – Deagglomerated

Select options This product has multiple variants. The options may be chosen on the product pageAluminum Oxide or Alumina – Aluminum oxide or alumina exists in two allotropic forms (1) alpha, which has a hexagonal crystal structure, and (2) gamma, which has a cubic crystal structure. Alpha alumina removes metal faster and is more suitable for rough polishing, while gamma alumina has slower metal removal rates but produces a better finish. Gamma B (0.05 micron) is used for final polishing steps, typically on a Suncloth Polishing Cloth. Aluminum oxide is excellent for most etch-attack polishing methods.

-

Aluminum Oxide Polishing Slurry

Select options This product has multiple variants. The options may be chosen on the product pageAluminum Oxide or Alumina – Aluminum oxide or alumina exists in two allotropic forms (1) alpha, which has a hexagonal crystal structure, and (2) gamma, which has a cubic crystal structure. Alpha alumina removes metal faster and is more suitable for rough polishing, while gamma alumina has slower metal removal rates but produces a better finish. Gamma B (0.05 micron) is used for final polishing steps, typically on a Suncloth Polishing Cloth. Aluminum oxide is excellent for most etch-attack polishing methods.