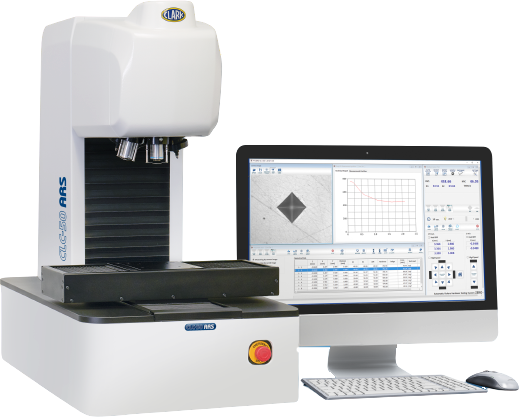

CLC-10 / CLC-50

CLC-ARS

FULLY-AUTOMATIC VICKERS / KNOOP HARDNESS TESTING SYSTEM

The ARS System is a fully automatic testing system that allows for programming, indenting, auto-reading, viewing and recording data all from one convenient station. It offers a variety of platforms ranging from standard auto-read measuring and reporting to fully automatic; making reading, conversions and reporting easier than ever before.

- Instant HV or HK Hardness Chart Display

- Multi-data Measurements

- Quick Measurement Indentation for Easy Edits and Image Archives

- Convenient Data Transfers, Reports and Storage

- Z-Axis Memory Feature

Special Features

REAL-TIME HARDNESS TEST RESULTS AT YOUR FINGERTIPS

The CLC-10 and the CLC-50 are designed with an expansive work area for testing large samples. Each utilizes a motorized Z-axis system that can accommodate up to 110mm (CLC-10) or 210mm (CLC-50) sample heights. Models are available with either a manual X-Y stage ((X) 50mm x (Y) 50mm) or an automatic motorized X-Y stage((X) 225mm x (Y)) 180mm, for greater control.

SPECIFICATIONS | CLC-10 AR / CLC-10 ARS | CLC-50 AR / CLC-50 ARS |

| TEST LOADS | ||

| VICKERS (HV) | 0.01, 0.02, 0.025, 0.05, 0.1, 0.2, 0.3, 0.5, 1, 2, 2.5, 3, 5, 10 kgf | 0.05, 0.1, 0.2, 0.3, 0.5, 1, 2, 2.5, 3, 5, 10, 20, 30, 50 kgf |

| KNOOP TEST LOADS (HK) | 0.01, 0.025, 0.05, 0.1, 0.2, 0.3, 0.5, 1, 2 kgf | 0.05, 0.1, 0.2, 0.3, 0.5, 1, 2 kgf |

| BRINELL TEST LOADS (HBW) | 1/1, 1/1.25, 1/2.5, 1/5, 1/10, 1/30, 2.5/6.25, 2.5/7.8125 mm/kgf | 1/1, 1/1.25, 1/2.5, 1/5, 1/10, 1/30, 2.5/6.25, 2.5/ 7.8125, |

| OPTIONAL LOAD SETTINGS | Max of 64 types of test loads – 0.01~10kgf (min 0.01kgf ) | Max of 64 types of test loads – 0.05~50kgf (min 0.01kgf ) |

| LOADING SYSTEM | Automatic Direct Loading System with Load-Cell feedback | Automatic Direct Loading System with Load-Cell feedback |

| LOAD-CELL(s) | 0.01~10kgf: using 2 Load-Cells | 0.05~50kgf: using 2 Load-Cells |

| FOCUSING METHODS | Automatic Operation or Manual Operation (using motorized Z Axis System) | Automatic Operation or Manual Operation (using motorized Z Axis System) |

| TURRET ROTATION | Automatic-Motorized | Automatic-Motorized |

| MEASUREMENT OF INDENTATION | Automatic Reading/Manual Reading | Automatic Reading/Manual Reading |

| LOAD APPLYING SPEED | Initial Descending Speed Approximately 180μm/s Effective Loading Speed Approximately 30μm/s for under 1kgf Test Load and Approximately 80μm/s for over 1kgf Test Load | Initial Descending Speed Approximately 180μm/s Effective Loading Speed Approximately 30μm/s for under 1kgf Test Load and Approximately 80μm/s for over 1kgf Test Load |

| DWELL TIME | 5 ~ 99 sec | 5 ~ 99 sec |

| INDENTER | Vickers Test (HV): 1pc (optional) Knoop Test (HK) and Brinell Test (HBW): Tungsten Ball ǿ1mm ǿ2.5mm | Vickers Test (HV): 1pc (optional) Knoop Test (HK) and Brinell Test (HBW): Tungsten Ball ǿ1mm ǿ2.5mm |

| OBJECT LENS | Infinity Corrected Long Working Distance (LWD) Lens 1pc: X10 & X50 (Optional X1.25, X2.5, X5, X20, X40 or X100) | Infinity Corrected Long Working Distance (LWD) Lens 1pc: X10 & X50 (Optional X1.25, X2.5, X5, X20, X40 or X100) |

| INDENT MEASUREMENT SYSTEM | Camera: automatic measurement using 1.3 MP | Camera: automatic measurement using 1.3 MP |

| SOFTWARE | ARS (Windows10®/64bit) | ARS (Windows10®/64bit) |

| OUTPUT SIGNAL | USB (RS232C converter: built-in) | USB (RS232C converter: built-in) |

| DIMENSIONS | Manual 110X110 mm / Auto 150X150 mm | Manual 110X110 mm / Auto 150X150 mm |

| X-Y STAGE MOVEMENT | Manual (X) 50mm x (Y) 50mm / Motorized (X) 225mm x (Y)180mm (mouse or joystick control) | Manual (X) 50mm x (Y) 50mm / Motorized (X) 225mm x (Y)180mm (mouse or joystick control) |

| MAX. HEIGHT OF SPECIMEN | 110 mm From Manual / Motorized Stage Top | 210 mm From Manual / Motorized Stage Top |

| MAX. DEPTH OF SPECIMEN | 180mm | 180mm |

| LIGHT SOURCE | LED Illumination | LED Illumination |

| ACCURACY | Vickers(HV) / Knoop(HK) Test: Conforms to tolerances per ASTM E92 and ISO 6507-2, ISO 4545-2 Brinell(HBW) Test: Conforms to tolerances per ASTM E10 and ISO 6506-2 | Vickers(HV) / Knoop(HK) Test: Conforms to tolerances per ASTM E92 and ISO 6507-2, ISO 4545-2 Brinell(HBW) Test: Conforms to tolerances per ASTM E10 and ISO 6506-2 |

| SAFETY DEVICE | Protection Cover on Turret for indenter(s) & Each Objective Lens(s) | Protection Cover on Turret for indenter(s) & Each Objective Lens(s) |

| DIMENSIONS | H 720 (28.3”) X W 415(16.3”) X D 650(25.6”) mm | H 820 (32.3”) X W 415 (16.3”) X D 650 (25.6”) mm |

| WEIGHT | Approximately 100kg (220 lb.) | Approximately 100kg (220 lb.) |

| POWER SUPPLY | 1P AC100~120V / AC240V(50/60Hz): selectable by switch | 1P AC100~120V / AC240V(50/60Hz): selectable by switch |